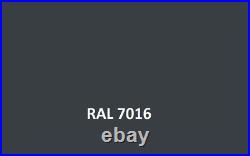

Discounted due to old stock, the paint is new and unused even if the tin itself. C5 Corrosion Class – Very High Protection!! Single Pack and Easy to Use. Elastomeric – Up to 200% Elasticity. Single pack water-based elastomeric coating based on a modified acrylic binder with unequalled corrosion protection. Not the product you need? On iron, steel, special alloys, galvanised and metallised iron and steel, aluminium, copper, zinc, lead, etc. As rust prevention or waterproofing. For outside and inside use. Diluted with 25% water as an adhesion primer coat on slightly or non porous substrates such as glass, smooth bricks and concrete, ceramics, tiles, etc. Please refer to the product Data Sheet for more uses. To request a copy. Further Details and Technical Data. Remove grease, oil and all other surface contaminations by alkaline or high pressure (steam) cleaning max. 200 Bars in combination with appropriate detergents. The substrate has to be dust free and made rust free by means of sandblasting (Sa2, St2) or high pressure water jetting min. After jetting, the substrate has to be dust free. On new galvanised surfaces, new zinc, aluminium, stainless steel, apply first a coat of Pegalink. On ferrous substrates, apply Noxyde in red or grey as the first coat. In all instances apply contrasting Noxyde colours for subsequent layers. Conditions: Temperature between 8 and 55°C / Air humidity max. The substrate temperature must be at least 5°C above dewpoint. Brushing: Undiluted as a rust preventive paint. Diluted with approximately 25% volume water as an adhesion primer (consumption about 100 g/m²). Roller: Undiluted as a rust preventive paint. Nozzle: 13 – 17 / Pressure: min. Nozzle and pressure can vary depending on the type of substrate, equipment and the experience of the applicator. Brush/roller: 200 – 300 g/m²/coat. Airless: 300 – 500 g/m²/coat. Total consumption for optimal rust preventive protection: 800 g/m² (in 2 coats) = 350 µm dry film thickness. Do not apply in full sun or too hot conditions, to avoid a decreased flow. The product can remain a little sticky if it is used on newPlastisol cladding. Touch dry: 1,5 hours. Dry to handle: 3 hours. Dry to recoat: 24 hours. Fully cured: 2 weeks. Density (g/cm³): 1,2 – 1,3. Gloss level at 60º: 20%. Corrosion Class: C5 very high protection. Solids Content in weight: 62 % ± 3 %. Solids content in volume: 55 % ± 3 %.