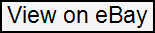

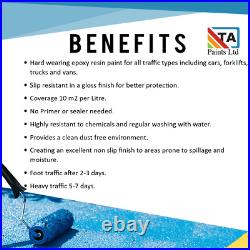

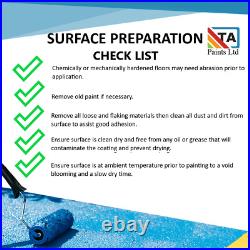

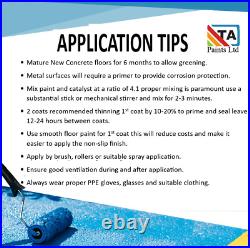

C Paints Ltd do it right First Time Every Time. Heavy Duty Two Pack Epoxy. Heavy Duty Two Pack Epoxy Floor Paint is suitable for use on concrete floors where heavy traffic will occur. For use on garage, industrial factory, warehouse, industrial kitchen and shop floors to provide a highly protective and hard wearing coating with excellent chemical resistance, also to be uses as a dust sealer for concrete floors. Two Pack Epoxy is based on an epoxy resin that provides an excellent hard wearing coating once fully dry, with a mirror like gloss finish to concrete floors. Please note although Epoxy coating’s offer the best chemical resistance and protection from the elements, the colours will chalk and fade in external applications. Mixing Two Pack Epoxies. Make sure you use a broom stick, mixer on a slow running drill or pallet knife to mix. (An egg whisk, screwdriver or small stick that doesn’t reach the bottom of the can is not sufficient enough). Mixing should take place for 3-5 minutes allow to stand for a minute and repeat. Mix the catalyst in to tub before tipping into a paint tray. Ensure all the content is properly mixed to avoid colour and or drying problem. New 3 In 1 Formulation. NEW 3 IN 1 TECHNOLOGY – Primes Seals and Protects with just 2 coats. No Primer or sealer for concrete. About Two Pack Epoxy Resin Paint. No Primer or sealer, Just 2 coats of this epoxy floor & garage paint will prime seal and protect. FLOOR PAINT: Two part epoxy based resin with a High Quality Durable finish. HARD WEARING EPOXY FLOOR PAINT – Stands up to heavy uses such as in areas where vehicles are regularly used, perfect for home and industral garages & factories. TOUGH EPOXY FORMULA – Dosent rip up like single pack floor paints where heavy traffic is used like cars and plant. EASY TO USE 2PK EPOXY FLOOR PAINT – Mixing ratio 4 parts paint to 1 part hardner mix well, Apply by brush or roller, solvents are strong in this epoxy paint so solvent resistant brushes and rollers will be required. Thinners if required T0200. Proudly manufactured in England by B. Please note images and product titles are for advertising purposes only, tins are supplied in BC Paints cans or plain white for, 1 and 2.5, and occasionally 5 litre cans. Easy to apply by brush and roller. Two coats of paint are recommended for the best longest lasting finish. Remember good preparation of the floor is paramount to an excellent long lasting finish. Make sure Floor is clean from dust, dirt, moisture, oil etc before painting. And never pre seal the floor prior to painting, especially with latex or PVC sealers paint will not stick. Brushes and rollers will need to be solvent resistant. Painting your Floor Step By Step. The floor area must be clean and free from dirt, dust, oil, grease and be dry & clear of any other contaminants. Good preparation is key to a good finish. Before you start, have your ppe ready as our paint is oil based so will not wash off easily with soap and water. Stir the paint & catalyst together well before use (4-1 mixing ratio), with a paddle on a slow running drill or substantial stick. Thin the first coat by 10 percent, to assist good priming and sealing of the floor. Before putting paint on the floor ensure you have good ventilation to allow vapor to escape, ventilation is also necessary to keep the drying times, if there is no air movement the coating cannot dry as well. Cut in around the edges first with a 2 to 3 inch brush, then work backwards towards your exit so as not to get boxed in. When painting large areas it’s easier to pour the paint on the floor in stages, spread it out using a squeegee then back roll with a roller to release the air, to avoid having a bubbly finish as the air is trapped in the coating during the drying process. Apply a second coat 12-24 hours (overnight dry) after the first coat to build good colour and protection. Always stir any paint well prior to using. Especially when using Two Pack products. Make sure you use a broom stick, mixer on a slow running drill or pallet knife to mix and mixing should take place for 3-5 mins to ensure all the content is properly mixed together to avoid colour and or drying problems. As our coatings are heavily pigmented separation can easily occur and you can have colour float, for example a green paint can seem blue before mixing, this is one of the reasons mixing your paint before use is essential. Or will need time to green this generally is a period of 3-5 months from when the concrete floor is layed, we say 3-5 months as it depends on the thickness of the concrete and quality, it’s always best ask the supplier and fitter of the concrete floor as to how long to wait till painting. Do not apply Two Pack Epoxy Paint in temperatures below 10 degrees centigrade cross linking of the paint and catalyst will not take place and the coating will never fully dry. C Paints Ltd is a family run company and are proud to have a long running heritage in the world of paint, as we are now in our 4th generation holding a combined experience of 100 years plus. C Paints Ltd produces all coatings in a midlands based production facility, manufacturing only from the finest virgin raw material. Throughout the years our ethos has been the same, to offer a fair product for a fair price, and never compromise quality for price.